What Does machining Mean?

What are the constraints of precision machining? There are actually courses for college kids who can take precision machining. An organization known as Preference Precision Machine states There's not limitation of length or job In relation to store producing.

Precision machined objects are about in daily goods for instance motor vehicle engines, electric motors or maybe clocks. Nations for instance Switzerland and Germany Possess a name for there large criteria of precision engineering and now nonetheless do a very good job of it. Other nations also have a lesser of this track record including Japan and Excellent Britian.

Ample R&D spending most likely would not have occurred in the device Device market alone; but it had been to the latter purposes that the will and ability to spend was available. When the development was underway, it absolutely was eagerly placed on equipment Resource Manage in among the many write-up-WWII scenarios of technological know-how transfer.

precision machining No Further a Mystery

At the time that Slice is finished, I'd like to remove every one of the tooling marks made by the end mill. If I consider employing a belt sander or even manually sanding, I get a good end, but find yourself inevitably rounding my great flat floor.

Increase interchangeability of parts to ensure corresponding elements created by other factories or companies can be utilized in their location.

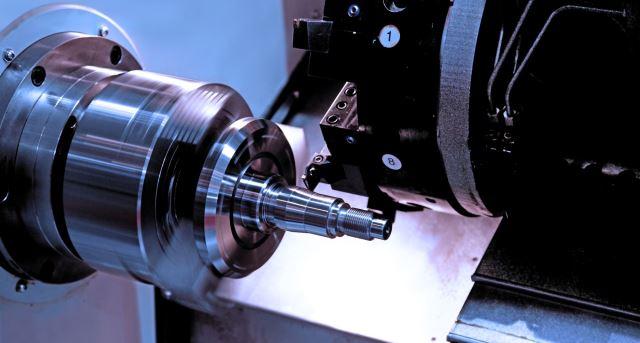

The milling method removes content by doing a lot of different, tiny cuts. This is completed by making use of a cutter with numerous tooth, spinning the cutter at large velocity, or advancing the fabric throughout the cutter slowly and gradually; most often it is some mixture of these three strategies.

Prior to numerical Manage, horizontal milling machines progressed 1st, mainly because they advanced by Placing milling tables beneath lathe-like headstocks. Vertical mills appeared in subsequent decades, and add-ons in the form of increase-on heads to alter horizontal mills to vertical mills (and later on vice versa) are actually normally utilised.

The Keeping system for HSK tooling is put throughout the (hollow) system on the Software and, as spindle speed increases, it expands, gripping the Instrument more tightly with growing spindle velocity. There is absolutely no pull stud with this kind of tooling.

5 Simple Techniques For precision machining

What does precision signify? Precision usually means in regards to the similar point as accuracy. It defines the doable or real deviation from the precise remedy.

Our prototype boxes and addresses can be employed for a wide variety of purposes and machined in many different plastics or metals.

Justification me for my confined vocabulary but is there an milling (little bit?) Which i full article can use for making ending passes, to remove These Software marks?

Conversely, with a CNC mill the rotating slicing tool moves round the workpiece, which continues to be set to the bed. Mills are all-purpose CNC machines which can handle most any machining method.

The Basic Principles Of machining

CNC Industries wholeheartedly agrees that information and facts management is very important to a business’s success. Their details method has saved them plenty of several hours and has facilitated practically fantastic On-time Delivery and Good quality effectiveness.